Petzl Ok

Availability: NZ stock Dispatch: 5-7 working days

NZ Stock items are dispatched either from our own warehouses or directly from our key suppliers. The dispatch time indicates the expected period for your order to be processed, including picking and packing.

Shipping

more info...

Shipping

more info...

Petzl Ok - Ball-Lock / Grey is backordered and will ship as soon as it is back in stock.

Description

Description

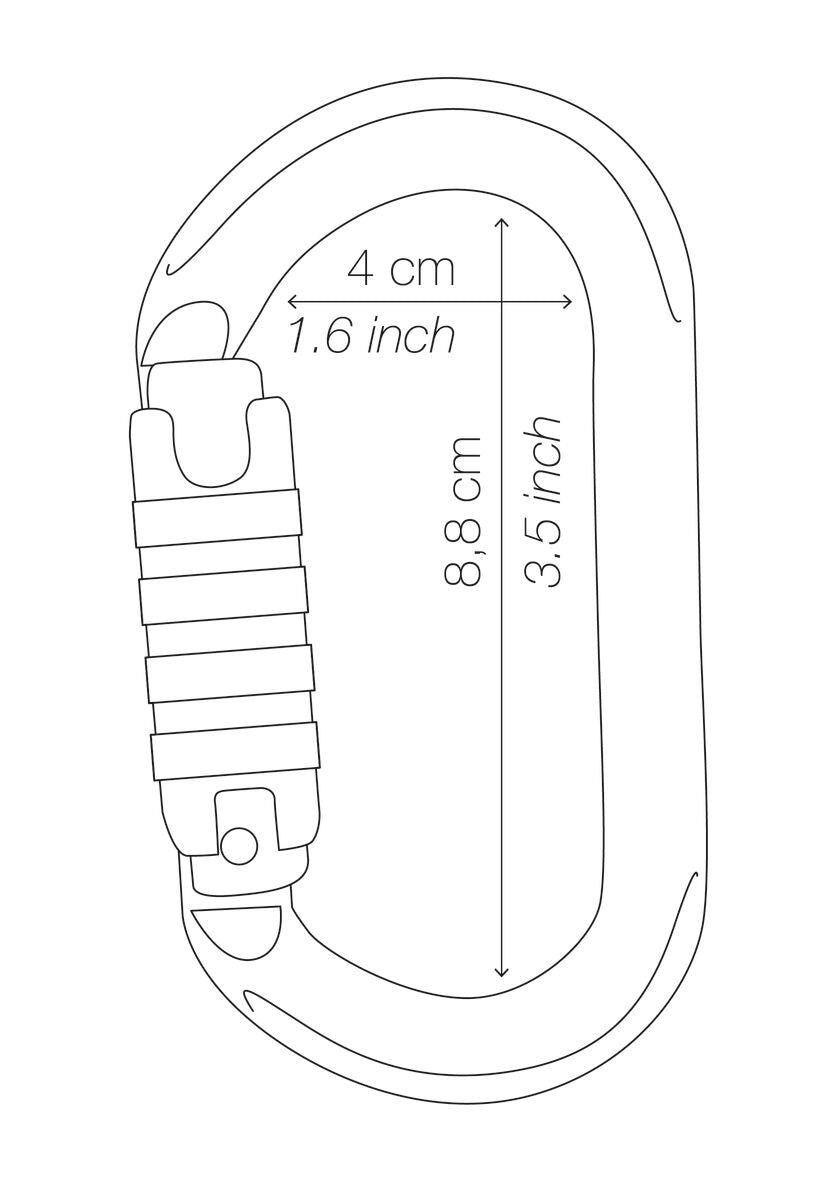

The Petzl Ok is a lightweight carabiner constructed from durable aluminum. Its unique oval shape is specifically designed for optimal loading of various devices, including pulleys, rope clamps, and fall arresters. The interior features a fluid design and Keylock system for effortless handling. Choose from three locking systems - automatic TRIACT-LOCK or BALL-LOCK, or the manual SCREW-LOCK - to suit your needs. To prevent flipping and maintain integration with the device, the OK can be connected to the CAPTIV bar for proper positioning along the major axis.

Features

- The symmetrical oval shape optimises the loading of devices with a broad cross-section, such as pulleys, rope clamps, and mobile fall arresters.

- The aluminium carabiner offers a lightweight solution, reducing the overall weight of equipment that a worker at height needs to carry.

- It may be paired with a CAPTIV positioning bar to encourage loading along the major axis, keep the carabiner aligned with the device, and minimise the risk of flipping.

-

Easier handling:

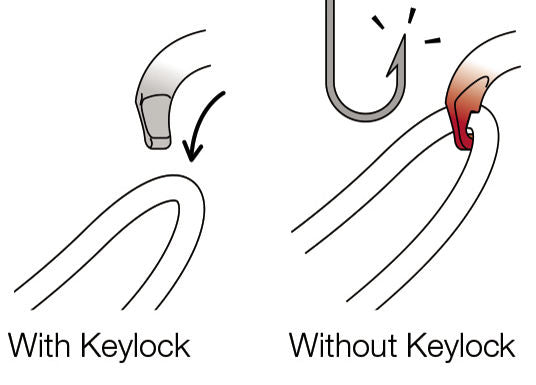

- The smooth interior design reduces the likelihood of snagging and facilitates seamless rotation of the carabiner.

- The Keylock system prevents accidental snagging, enhancing overall ease of use.

-

H cross-section:

- Ensures an optimal balance between strength and weight.

- Protects markings from abrasion, preserving legibility over time.

-

Available in three different locking systems:

- TRIACT-LOCK: Features automatic locking with a triple-action gate opening mechanism.

- BALL-LOCK: Provides automatic locking with a triple-action gate opening and includes a lock indicator for added safety.

- SCREW-LOCK: A manual screw-lock system with a red band that offers a visual indication when the carabiner is unlocked.

Specifications

| Material(s) | Aluminum |

| Certification(s) | CE EN 362, 12275 type B, EAC, GB/T 23469 / B, XF 494:FZL-G-Q |

| Weight | 75 g | 75 g | 70 g | 70 g |

| Locking system | TRIACT-LOCK | BALL-LOCK | SCREW-LOCK | SCREW-LOCK |

| Colour(s) | Grey | Grey | Grey | Black |

| Major axis strength | 25 kN | 25 kN | 25 kN | 25 kN |

| Minor axis strength | 8 kN | 8 kN | 8 kN | 8 kN |

| Open gate strength | 7 kN | 7 kN | 7 kN | 7 kN |

| Gate opening | 22 mm | 23 mm | 22 mm | 22 mm |

| Inner Pack Count | 1 | 1 | 1 | 1 |

Technology

Technical Notice

Declaration Of Conformity

- Download the PDF : UE-Declaration-M33A-BL-OK-Ball-Lock - 0.65 MB

- Download the PDF : UE-Declaration-M33A TL-M33A-TLN-OK-Triact-Lock - 0.65 MB

- Download the PDF : UE-Declaration-M33A-SL-SLN-OK-Screw-Lock - 0.65 MB

Tips for maintaining your equipment

Inspection

PPE inspection procedure

PPE checklist

Technical Content

CARABINER LOCKING SYSTEMS

The various systems meet different needs for each application, for a precise balance between ergonomics and safety.

SCREW-LOCK (SL)Classic manual system, versatile and universal |

ERGONOMICS

Advantages:

- The sleeve locks manually, only when desired by the user

- Can be operated with one hand

Disadvantages:

- The time it takes to lock the sleeve

SAFETY

Advantages:

- Reliability in dirty or harsh environments

- Red visual indicator, when unlocked, to facilitate monitoring

- The user actively operates the sleeve when locking, so they are immediately alerted in case of bad locking

Risks:

- Vibrations can unlock the sleeve

- Rubbing can unlock the sleeve

- Risk of forgetting to lock the sleeve

TWIST-LOCK (RL)Auto-locking and double action opening system |

ERGONOMICS

Advantages:

- Speed and ease of opening

- Rapid auto-locking

Disadvantages:

- Sleeve must be unlocked each time the carabiner is opened

- Two hands needed to insert a device into the carabiner

SAFETY

Advantages:

- Rapid auto-locking

Risks:

- Chance of improper locking when the carabiner closes (e.g. sling caught between the nose and the gate). The user must verify that the carabiner is properly closed and locked, even when using an auto-locking system

- Sensitivity to rubbing by rope or equipment: the sleeve can accidentally unlock and the gate come open in the same motion

WIRE-LOCK (WL)Auto-locking and double action opening system System designed specifically for the end of a lanyard |

ERGONOMICS

Advantages:

- Speed and ease of opening almost as easy as a non-locking carabiner

- Rapid auto-locking: system suited to very frequent connection and disconnection

SAFETY

Advantages:

- Rapid auto-locking

Risks:

- Less locking security than with other systems, yet offers more security than a non-locking carabiner

- Very sensitive to external pressure: the sleeve unlocks and the gate opens in the same motion

TRIACT-LOCK (TL)Auto-locking and triple action opening system |

ERGONOMICS

Advantages:

- Rapid auto-locking.

Disadvantages:

- Sleeve must be unlocked each time the carabiner is opened

- Tricky sleeve operation, requires practice

- Two hands needed to insert a device into the carabiner

SAFETY

Advantages:

- Security of triple action locking (excluding rubbing and external pressure)

- Rapid auto-locking

Risks:

- Chance of improper locking when the carabiner closes (e.g. sling caught between the nose and the gate). The user must verify that the carabiner is properly closed and locked, even when using an auto-locking system

- Sensitivity to mud or other foreign objects that can impede auto-locking

BALL-LOCK (BL)Auto-locking and triple action opening system |

ERGONOMICS

Advantages:

- Rapid auto-locking

- Visual locking indicator

Disadvantages:

- Sleeve must be unlocked each time the carabiner is opened

- Tricky sleeve operation, especially with gloves, requires practice. System is less "ambidextrous" than the others

- Two hands needed to insert a device into the carabiner

SAFETY

Advantages:

- Security of triple action locking (excluding rubbing and external pressure)

- Rapid auto-locking

Risks:

- Chance of improper locking when the carabiner closes (e.g. sling caught between the nose and the gate). The user must verify that the carabiner is properly closed and locked, even when using an auto-locking system

PIN-LOCK (PL)Auto-locking and triple action opening system with tool |

ERGONOMICS

Advantages:

- Long duration installation without manipulation

- Helps limit incorrect operation during use

- Helps prevent the user from becoming disconnected during use

Disadvantages:

- Complicated to disconnect in the field, for example in case of emergency

SAFETY

Advantages:

- Triple action locking gives great security, with a tool required for the first action

Risks:

- Chance of improper locking when the carabiner closes (e.g. sling caught between the nose and the gate). The user must verify that the carabiner is properly closed and locked, even when using an auto-locking system

EASHOOK / MGO System

Auto-locking and double action opening system

ERGONOMICS

Advantages:

- Speed and ease of opening

- Rapid auto-locking

- Good separation of the two actions required to open the gate

Disadvantages:

- Limited compatibility with anchors and equipment

- Carabiner rotation in equipment is impossible

SAFETY

Advantages:

- Good separation of the two actions required to open the gate

- Directional carabiner that helps promote major axis loading

- Rapid auto-locking

Risks:

- External pressure from the structure or equipment can unlock and open the gate

- The large size can increase the risk of cantilever loading depending on the supporting media

Semi Permanent Connectors (RING OPEN, quick links...)

Manual closing system with a tool needed for locking

ERGONOMICS

Advantages:

- Long duration installation without manipulation

- Helps limit incorrect operation during use

- Helps prevent the user from becoming disconnected during use

Disadvantages:

- Complicated to disconnect in the field, for example in case of emergency

- Tool required for assembly and disassembly

SAFETY

Advantages:

- Very secure locking if the initial tightening is done correctly

Risks:

- The initial locking must done correctly and carefully checked before use

- The large size can increase the risk of cantilever loading depending on the supporting media

CARABINER BASICS

The carabiner is an essential link in any vertical equipment kit. It is very strong when used correctly, but can break or come open if misused. Understanding the strengths and weaknesses of carabiners allows the user to make the most suitable choice for each application.

|

WARNINGS

|

|

A carabiner is designed to be loaded on the major axis, with the gate closed and the sleeve locked. Only the strength rating for the major axis with gate closed is suitable for the loads sustained by a carabiner in vertical activities. Loading a carabiner in any other way can be dangerous. |

Examples of Dangerous Carabiner Loading

|

The risks associated with incorrect loading can be reduced:

For each use:

Follow the instructions presented in your carabiners' Instructions for Use |

Balance between a carabiner's ease of opening and security of locking

A secure lock reduces the probability of accidental opening in use.

The most secure lock is that of a quick link tightened with a tool, with a near zero probability of accidental opening. But such a lock does not make for efficient operation in the field.

Ease of opening (ergonomics) enables quick and efficient connection and disconnection. In certain situations, this contributes as much to user safety as the security of the lock.

This balance must be finely tuned: the user must choose what is suitable for each type of use. The other parts of this document give details, based on the application, to aid the user in this choice.

| SECURITY (-) | SECURITY (+) | |

| ERGONOMICS (+) | ERGONOMICS (-) |

DIFFERENT CARABINER SHAPES

A good choice of carabiner shape can increase ergonomics and security for certain uses.

The shape of the carabiner frame has an influence on:

- Major axis strength

- Load distribution

- Gate opening size, and capacity

- Strength in certain positions

- Ease of handling

Another less obvious effect is the balance of the carabiner itself: for example pear-shaped carabiners rotate more readily, which can result in poor positioning. D-shaped carabiners tend to stay in place better.

D

|

OvalSymmetric shape for even loading (devices with a large attachment hole, pulleys...).

|

PearHigh capacity, for connecting multiple items or bulky items. |

Wide opening carabinerWide opening facilitates attachment to anchors, cables... |

OMNI Multidirectional Carabiner

|

Directional CarabinerTwo separate attachment areas to optimize loading on the major axis, for specific uses. |

CARABINER COMPATIBILITY TEST

Any time equipment is to be used with a new carabiner, a compatibility test is recommended.

Petzl does tests for Petzl products and carabiners; specific details on compatibility are mentioned in the Instructions for Use for the devices.

- Verify that the chosen carabiner is suitable for the intended use

- Verify that the carabiner's cross-section is suitable

- Check that the carabiner does not jam in the device's attachment hole

- Assess the possibility of the carabiner getting into a bad position and the stability of this bad position

- Check the risk of interference between the elements of the system and the carabiner sleeve

Note: For devices fitted with a flexible carabiner positioning piece (ZIGZAG, PIRANA...) repeat the compatibility test whenever you install a new carabiner. The flexible piece may have been deformed by the last carabiner, and may not correctly position the new one.

EXAMPLES OF DANGEROUS CARABINER LOADING.

A carabiner is strongest when loaded on the major axis, with the gate closed and the sleeve locked. Loading a carabiner in any other way can be dangerous.

Load Position

|

Barring exceptional circumstances, a carabiner is designed to be loaded on the major axis. Only the strength rating for the major axis with gate closed is suitable for the loads sustained by a carabiner in vertical activities. Loading on any axis other than the major axis, and any poor positioning, will result in reduced strength. |

THE PRIMARY RISKS

Risk of Unclipping |

|

Examples Examples |

The gate can come open if:

|

|

Risk of Carabiner Breakage Note: Vertical practices involving a single user who is properly equipped and protected from falls rarely generate enough force to break a carabiner. However, any fall can produce an impact force that approaches the breaking strength of a poorly positioned carabiner. |

|

|

|

Examples |

Examples |

Examples |

Examples |

Examples |

|

|

|

Examples |

Examples |

|

|

|

Examples of Risk Situations in the Field

|

1. OPENING OF THE GATE, OPEN GATE LOADING |

|

Opening of the gate > Release of the load/person |

Open gate loading > Risk of carabiner breakage |

| A carabiner with the gate open is weak: only 30 % of the major axis strength (e.g. 7 kN instead of 27 kN on the major axis for the Am’D). |

| 2. MINOR AXIS LOADING |

|

A carabiner loaded on the minor axis is weak: only 35 % of the major axis strength (e.g. 8 kN instead of 27 kN on the major axis for the Am’D). |

| 3. MULTIDIRECTIONAL LOADING |

|

The strength loss in a multidirectional load depends on the angle between the axes of loading. |

| 4. LOADING OVER AN EDGE |

|

A carabiner loaded over an edge is weak: only 30 % of the major axis strength (e.g. 6 kN instead of 23 kN on the major axis for the SPIRIT SL). This value varies greatly depending on the position of the edge (in the middle of the gate or closer to the nose...). |

|

5. OVERLOADED CARABINER The major axis strength of a carabiner is optimal when the load is closest to the spine side of the frame. If the load shifts to the gate side, the strength is reduced. |

|

Strength loss is most pronounced with a pear-shaped carabiner, as the nose is rather far from the spine side of the frame. Their shape also contributes to poor positioning of the load. A carabiner loaded on the gate side is weak: only 30 % of the major axis strength (e.g. 7 kN instead of 27 kN on the major axis for the WILLIAM). |

| 6. VARIOUS CANTILEVER LOADS |

|

The different cantilever positions are too numerous to be exhaustively tested. The strength of a carabiner in this case can be less than 30 % of the major axis strength. A pronounced cantilever load can also damage the supporting device or anchor. |

| 7. PRESSURE ON THE SLEEVE (RISK OF SLEEVE DAMAGE) |

|

|

|

The locking sleeve is the weakest part of your carabiner. The European standards require a sleeve strength of 1 kN under external pressure (a value easily reached in the field). Certain standards require much higher strengths, for example 16 kN for the ANSI Z359.12 standard. |

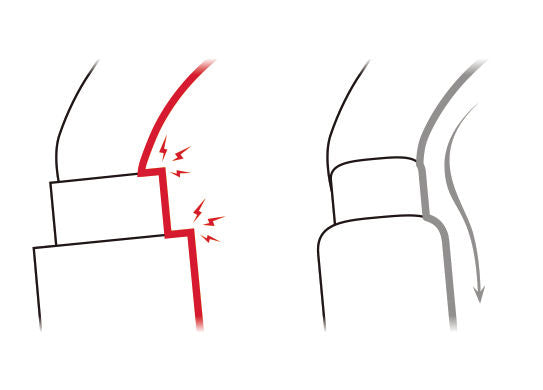

| 8. RUBBING ON THE SLEEVE (RISK OF OPENING THE SLEEVE AND GATE) |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Shipping

Shipping